Methodology

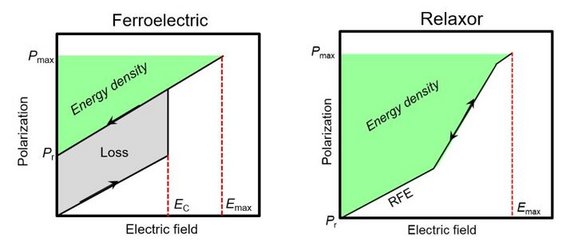

In dielectric capacitors, the energy density is defined as the integral of polarisation vs. the applied electric field. The recoverable energy density (i.e. upon capacitor discharge) is then the stored energy density minus the hysteretic losses, which in ferroelectric materials are due to ferroelectric domain switching. From Figure 1 it is evident how a high recoverable energy density is obtained by:

- Minimising the remanent polarisation Pr

- Maximising the maximum polarisation Pmax

- Maximising the applied electric field Emax.

The remanent polarisation decreases if the long-range correlation of B-site displacements in the ABO3 perovskite crystal is disrupted, for example by B-site doping. This, however, induces also a decrease in Pmax.

CITRES Goal 1:

In the CITRES project, we will design a lead-free ABO3 perovskite composition that enables minimising the remanent polarisation while at the same time maintaining high Pmax. This will be done by combined A- and B-site doping of BaTiO3 to finely tune polar order at the B-site and decouple the polar response of A- and B- sublattices. This way, we aim to maintain high dielectric permittivity even when the B-site polar correlation is disrupted.

The applied electric field can be maximised by enhancing the dielectric breakdown strength and reducing leakage currents.

CITRES Goal 2:

In the CITRES project, we will produce relaxor-based capacitors using thin film technology. Since thin films have high density and less defects compared to ceramics, the dielectric breakdown strength will be enhanced. Furthermore, we will design a multilayer structure at the interface between electrode and dielectric and choose the right electrodes and buffer layers to minimise leakage currents.

CITRES Goals 1 and 2 will be reached by:

- Using thin film technology to deposit dielectric layers and buffer layers to produce single- and multilayer capacitors.

- Studying the polar order in relaxors over several length scales (atomic-nano-micro) to determine the influence of dopants on the remanent polarisation and permittivity in capacitors – aiming to high recoverable energy density.

- Studying the electrode/dielectric interface structure and linking it with electric conductivity and leakage currents.

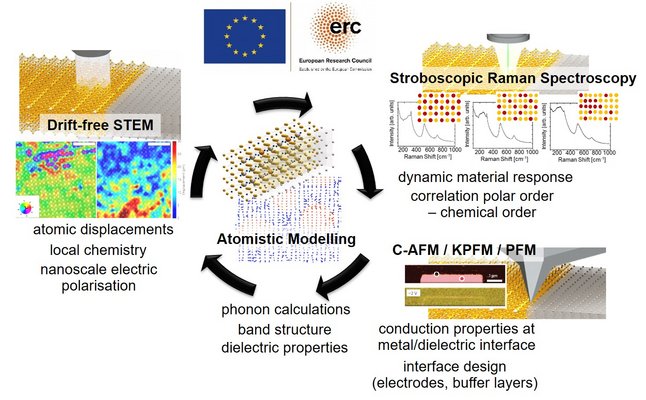

We will use a combination of several methodologies to perform these studies, in particular:

- Thin film processing (sol-gel)

- Macroscopic dielectric/ferroelectric measurements

- Drift-free scanning transmission electron microscopy (STEM)

- Stroboscopic Raman spectroscopy

- Conductive- and Kelvin Probe Force Microscopy

- Atomistic modelling

- Data driven materials design

All these methodologies will be combined in a package specific to CITRES, providing mutual feedback towards the goal of designing relaxor compositions and capacitor systems with high recoverable energy density.

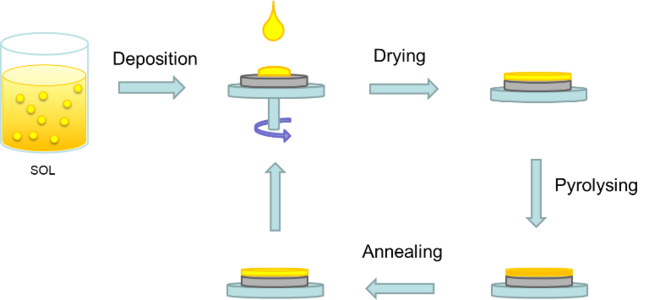

Sol-gel synthesis and thin film deposition

One of the goals of CITRES project is to enhance the dielectric breakdown strength to maximise the applicable electric field on ceramic dielectric capacitors. To reach it, it is of fundamental importance to limit the presence of defects and porosity, achieving a thin, dense material. Thin films are the best candidates for multilayer capacitors and one processing technique that has attracted a lot of interest due to the easiness and low cost, is the chemical solution deposition (CSD) coupled with spin-coating.

The first step in the processing of the thin films is the synthesis of the precursor solution. This is done via the sol-gel method, where metal-alkoxides are mixed according to the stoichiometry in a solvent. The solution is then deposited on wafers (for example, platinised silicon) using the spin-coating technique that ensures a high control on the thickness of each layer and a good homogeneity. The deposited films are then annealed in a furnace and the process is repeated until the desired thickness is achieved.